Socks Wear Tester

Availability: In Stock

Brand: AdLab

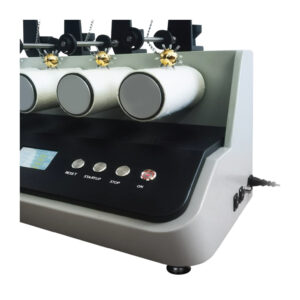

Model: ADL-SWT2

Origin: Europe

- Tests wear and tear resistance of socks, per EN 13770-2002.

- Features adjustable friction and reciprocating stroke, dual workstations.

- Servo motor, low noise, large touch screen, and bilingual interface.

Standards of the Socks Wear Tester

EN 13770-2002 Textiles – Determination of wear resistance of knitted footwear – Method C

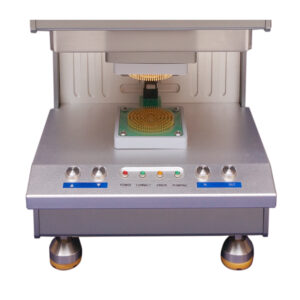

Testing Principle

Install the sample on the testing mold, rub the sock sample with sandpaper at a constant speed, and cycle every 100 or 500 times to observe if the sample is damaged or thinning. If so, record the number of times.

Product Features

- The manufacturer finishes the electric control box with metal baking paint for durability.

- It features an imported special aluminum brushed panel, providing an elegant and professional appearance.

- Moreover, the transmission sliding mechanism uses imported linear sliders, ensuring smooth operation with no vibration.

- The manufacturer treats the base with a metal baking paint process for enhanced durability.

- The sampling handwheel uses thread locking, offering good friction and preventing slippage.

- Additionally, it includes a large color touch screen with a user-friendly interface, supporting both Chinese and English languages.

- Furthermore, the servo drive and motor ensure stable, adjustable speed with extremely low operating noise.

- The design equips the leg surface with imported cork for added functionality.

Key Specification

- Friction Frequency: 1-999,999 times (adjustable)

- Reciprocating Stroke: 1-30mm

- Workstations: 2

- Reciprocating Frequency: 125 times/min

- Power Supply: AC220V ± 10%, 50Hz

- External Dimensions: 650mm x 600mm x 580mm (L x W x H)

- Weight: 45kg

Why Choose the Socks Wear Tester?

The Socks Wear Tester is an essential tool for manufacturers aiming to ensure the durability of socks. Since wear and tear resistance directly impacts the longevity and quality of knitted footwear, this tester simulates real-world conditions by rubbing the sock sample with sandpaper at a constant speed. For instance, it cycles every 100 or 500 times to observe if the sample is damaged or thinning, recording the number of cycles for accurate analysis. Moreover, its user-friendly features, such as the large color touch screen and bilingual interface, make it easy to operate in any lab. Consequently, manufacturers can ensure their socks meet standards like EN 13770-2002, improving product reliability. For more details on how this equipment can enhance your testing process, please Contact with AdLab

Reviews

There are no reviews yet.